RTM & FRP

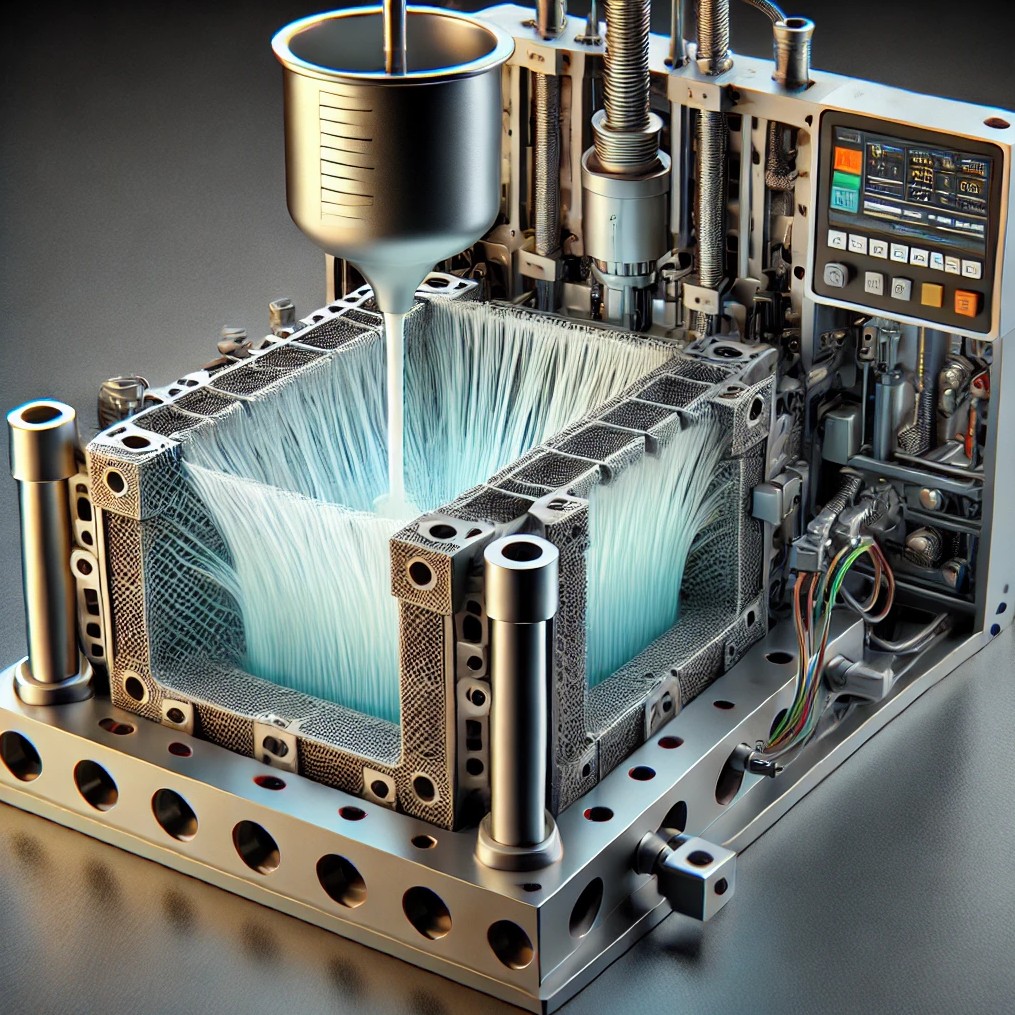

RTM is a closed-mold process where a dry reinforcement (like fiberglass or carbon fiber) is placed into a mold and then a liquid resin is injected into the mold under pressure.

Resin Transfer Molding (RTM)

RTM is a closed-mold process where a dry reinforcement (like fiberglass or carbon fiber) is placed into a mold and then a liquid resin is injected into the mold under pressure.

Once the resin fully saturates the reinforcement and cures, the result is a strong, lightweight composite part.

This method is widely used in industries like automotive, aerospace, and marine for creating high-quality structural components.

Fiber-Reinforced Polymer (FRP)

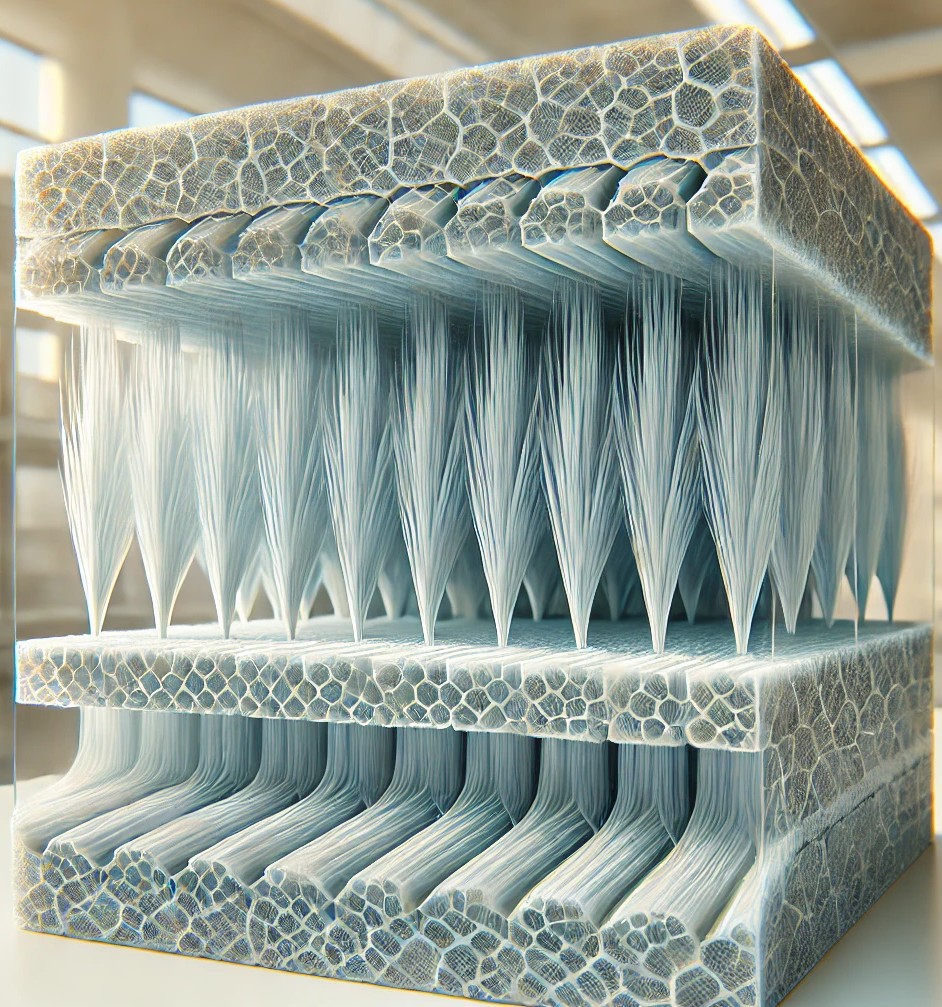

FRP refers to composite materials made from a polymer matrix reinforced with fibers such as glass (fiberglass), carbon (carbon fiber), or aramid (Kevlar).

FRP composites are popular for their strength-to-weight ratio, corrosion resistance, and design flexibility.