ADDITIVE MANUFACTURE

Prototyping is a critical step in product development, where a physical or virtual model is created to test the design, functionality, and manufacturability of a product before large-scale production. This stage helps in identifying potential design flaws, verifying product performance, and making necessary modifications.

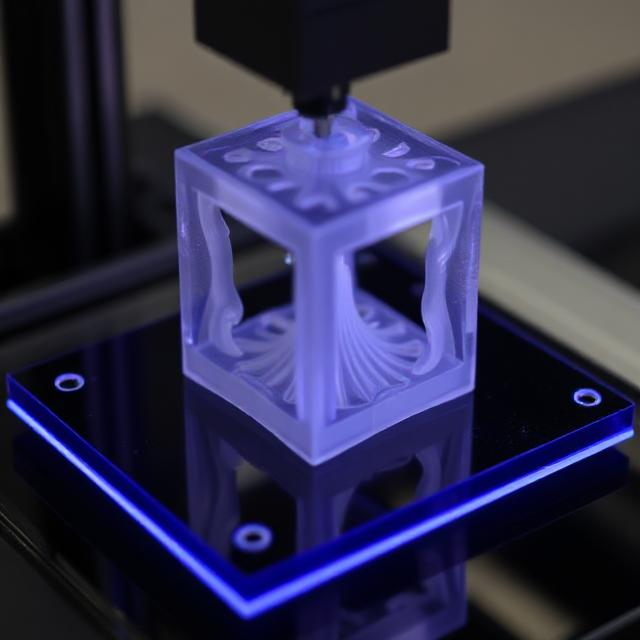

STEREOLITHOGRAPHY (SLA)

SLA is a high-precision 3D printing technology known for producing smooth surface finishes and intricate designs.

It uses photopolymer resins and is ideal for creating visual models, detailed prototypes, and parts requiring tight tolerances.

SLA delivers exceptional accuracy and is perfect for applications like product design, medical models, and concept prototyping.

SELECTIVE LASER SINTERING (SLS)

A 3D printing process that uses a laser to sinter powdered material into a solid structure.

Materials: Thermoplastics (e.g., nylon) and composite powders.

Used for functional prototypes and end-use parts, especially in industries like aerospace and automotive.

.jpg)

MULTI JET FUSION (MJF)

Multi Jet Fusion (MJF) is an advanced 3D printing technology developed by HP.

It is a powder-based additive manufacturing process that produces high-quality, detailed, and functional parts with excellent mechanical properties.

VACUUM CASTING

Vacuum casting is a manufacturing process used to create high-quality prototypes and small production runs of plastic or rubber parts.

It involves using silicone molds to replicate a master model under vacuum conditions, ensuring precise detail and minimal defects.